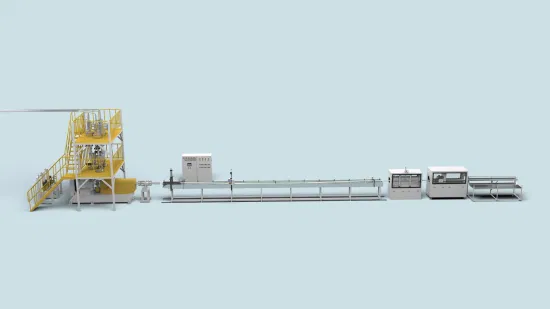

Light Steel Door Keel Stud Track Framing Machine

Package Size 750.00cm * 150.00cm * 180.00cm Package Gross Weight 5000.000kg Galvanized Light steel door keel stud track

Basic Info.

| Model NO. | HX-door frame machine |

| Automatic Grade | Automatic |

| CNC or Not | not CNC |

| Voltage | 380V |

| Hydraulic Pump | 5.5kw or Customer′s Need |

| Voltage Standard | 380V/3phases/50Hz |

| Motor Power | 7.5kw or Customer′s Need |

| Weight | 4.8tons |

| Decoiler | 1 Set Manual with Free |

| Size | 8*1.2*1.2meters |

| PLC System | Delta Brand, Taiwan |

| Shaft Material(Hard) | High Grade 45# Steel, Heated and Quenched, Cylindr |

| Shaft Diameter | 70mm |

| Forming Speed | 0-15m/Min |

| Roller Material | Bearing Steel, Quenching and Tempering |

| Roller Station | 16rows Plus Leveling Device |

| Main Frame | Square Steel Frame |

| Name | Light Steel Door Keel Stud Track Framing Machine |

| Transport Package | Main Body Plastic Film, Spare Parts Put Carton Box |

| Specification | 8*1.2*1.2Meters |

| Trademark | No |

| Origin | China |

| HS Code | 84552210 |

| Production Capacity | 200sets/Month |

Packaging & Delivery

Package Size 750.00cm * 150.00cm * 180.00cm Package Gross Weight 5000.000kgProduct Description

Galvanized Light steel door keel stud track framing machine Door Frame Making Machine can make various types metal door or window frames, reinforced, fire stop doors, etc by roll forming method. The steel door frame roll forming machineis a complete product line. After roll forming by our production line, we could make very smooth and beautiful steel door frame without any scratch on surface. This steel door frame production line is composed by the following elements: De-coiler, feed & leveling device, main roll forming machine, cutter, run-out table, etc. Those machines are customized according to the drawing profile.| Light steel door keel stud track framing machine | |

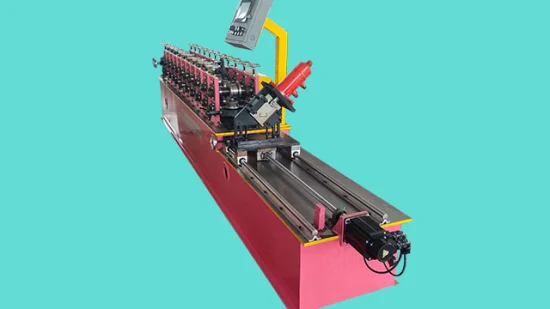

| Roll Forming Machine | Double door frame |

| Material width | 3 sizes. Waiting for buyer exactly profile |

| How to adjust size | Option : by PLC (It can be adjust by PLC and also in hand wheel)One side fixed and the other is adjustable by manual or PLC |

| Base frame | Base frame 30 mm thick steel plate process the surface on CNC planer to keep it leveling and drill boltes and key slot by CNC |

| Rolling Speed | 12-15m/min(not include cutting time) |

| Rolling Thickness | 1.2-2.0mm |

| Material | GI or metal |

| Control System | PLC (Panasonic) as list in the note |

| Un Coiler | 3 Ton manual decoiler |

| Leveling | Up in 3 roller, down in 4 roller |

| Roller Stations | About 16 stations |

| Roller Material | Gcr15, coated with chrome HRC58-62 degree |

| Shaft Material and DIA | ¢70mm, material is 45# forge steel |

| Maim Motor Power | 7.5kw brake motor |

| Hydraulic Station Power | 5.5kw |

| Hydraulic Pressure | 20Mpa |

| Capacity of tonnage for punching | 22Tons |

| Hydraulic pump brand | Lichao |

| Bearing brand | Harbin |

| Other brand list | PLC: Panasonic Touch screen: MCGSInverter: YaskawaMain components for low pressure electricity: Schneider Encoder: Omron |

| Punching | 3 units pre-punching and one unit cutting&punching include including 6 set 45 degree angle mouldsThe punishing tonnage to make the hole and cutting to make the 45 degree |

| Cutting | Hydraulic post-cutting for cut end product |

| Extra cutter | One more cutter for each profile |

| Material Of Cutting | Cr12Mov quenching 58-62ºC |

| Electric Source | 380V, 60HZ,3 phase |

| Way Of Drive | 1.2 inch single chain |

| Color Of The Machine | Yellow and blue |

| Machine Type | Iron Cast |

| Emergency switch | In main machine and control panel all have emergency switch for forbid any urgently accident |

| Protect cover | Complete mobile safty cover from roll forming to the cutter |

| Size of the machine | L*W*H 8m*1.2m*1.2m |

| Container Need | 1 x40 feet (base on final) |

| Passive Decoiler | 1Set |

| Feeding Platform with Pre-cutter | 1Set |

| Roll Forming Machine | 1Set |

| PLC Control System | 1Set |

| Hydraulic Cutting System | 1Set |

| Exit Rack for roofing production | 2Pieces 3Meters |

| Spare parts | One carton box |

Export standard packing of Light steel door keel stud track framing machine:1.The main body of the roll forming machine will be naked packing into the container,covered with plastic film. 2.Steel wire fix the machine into the container, in case any damage when shaking on the sea. 3.The spare parts will be packed into the carton box. 4.The received goods table put into carton box . 5.Manual decoiler naked package .After Sales Service of Light steel door keel stud track framing machine:1. Warranty :One year,and we will provide technical support for whole life of the equipment.2. Delivery time: Within 25 days after deposit receipt your payment3. Guarantee period: 24months free service/ pay service all the machine life4. Installation and trainingIf buyers visit our factory and check the machine, we will teach you how to install and use the machine and also train your workers/technician face to face.FAQ:Q: Are you a trading company or a factory?

A: We are factory with professional production team and service consciousness just for exporting various types of cold rollforming machines

Q: Can a machine produce only one style profile?

A: Not complete. Suitable for flowers design manufacturing machines. It can produce more than 3 kinds on one machine(change flower mold roller )Q: How long does it take to manufacture the machine?

A: In general, the machine can be completed in 20 to 35 business days. But if you need machines urgently, we can save you time

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and otherparts, processing, assembly, testing and packaging on the roll surface and shaft

Q: What can you do if the machine broken?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damagedpart, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue throughnegotiation and we provide technical support for the entire life cycle of the device

Q: What is your strength compared to other suppliers?

A: We will give you the best service. We will provide you with good advice that exceeds your requirements. These lines are easy toinstall and have low maintenance requirements

Q: Can we become your agent abroad?

A: Of course, if you have a business in the rolling forming line, we will welcome a lot of cooperation

Relative popular sell machines photos showing

Send to us