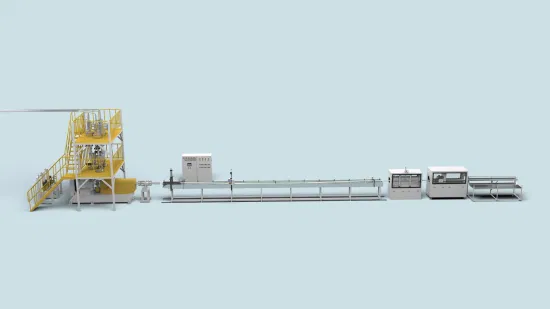

Steel Metal Roof Trapezoidal and Corrugated Iron Roofing Zinc Sheet Panel Roll Forming Machine

Double layer roll forming machine 1.How to maintain the machine? Answer: add mechanical lubrication equipment to chain,

Basic Info.

| Model NO. | Roof Sheet Making Machine |

| Usage | Roof, Wall, Floor |

| Transmission Method | Electric |

| Controller | PLC, Auto Count Length and Quantity |

| Main Base | H Steel Weld |

| Roller | Cr12, Chromed, Prevent Abrasionanti Corrosion |

| Rolling Shaft | 40cr, Tempering to Improve Hardness |

| Transport Package | Standard Export Package |

| Trademark | KEFA |

| Origin | Cangzhou |

| HS Code | 845522 |

| Production Capacity | 100/Pic/Year |

Product Description

Double layer roll forming machine

1.How to maintain the machine?

Answer: add mechanical lubrication equipment to chain, bearing and cutting slide every month. Add mechanical lubrication to the case every half a year.

2. Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

3.How many workers to operate the machine?

A:Only 1-2 workers.

4. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan Station to Cangzhou West Station(1 hour), then we can pick you up .b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou West station(4.5 hours), then we can pick you up.

5. What can you do if the machine broken?

Our machine's warranty period is 12months,if the broken parts can't be repaired,we can send the new parts to replace the broken parts for free,but you need pay the express cost yourself.if over warranty period,we can for to solve the problems via negotiation,and we supply the technical support for the whole life of the equipment.

6.How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference. Or,2) Please visit company and test machine if convenient.

previous:

Roll Forming Machine for Yx35

Send to us