2W/3W

Basic Info.

| Model NO. | Floordeck Panel Roll Forming Machine |

| Applicable Industries | Hotels, Garment Shops, Building Material Shops |

| Advantage | Easy Installation and Full Automatic Easy Operatio |

| Marketing Type | New Product 2022 |

| Operating Procedures | We Will Send You Operation Book with The Machine |

| Key Selling Points | High Productivity |

| After-Sales Service Provided | Online Support Video Technical Support |

| Sheet Profile Size | Customized According to Different Country |

| Sheet Type | Galvanized Steel Metal Roof Roofing Decking Profil |

| Production Name | Automatic Galvanized Steel Floor Decking Machine |

| Machinery Test Report | Provide |

| Voltage | 380V 50Hz 3phases or as Your Requirement |

| Product Name | Floordeck Panel Roll Forming Machine |

| Control Device | Full Automatic Control |

| Working Materials | PPGI/Gi/Aluminium/Galvanized Steel Metal Sheet |

| Transport Package | Customize |

| Specification | Cutsomized |

| Trademark | N/M |

| Origin | Botou, China |

| HS Code | 84552210 |

| Production Capacity | 500 Sets/Year |

Packaging & Delivery

Package Size 1100.00cm * 150.00cm * 150.00cm Package Gross Weight 9000.000kgProduct Description

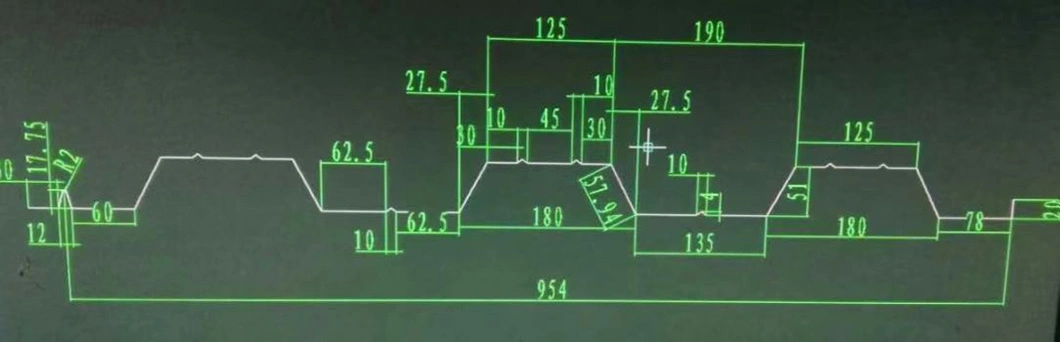

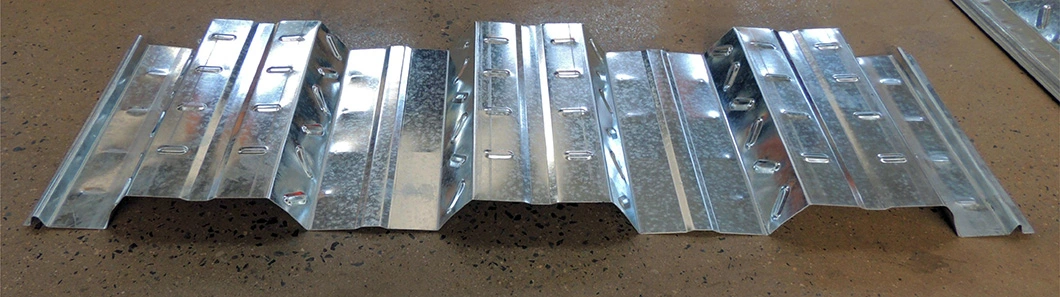

Product Description2W/3W-Deck Steel Decking Floordeck W Profile Ribdeck Structural Construction Steel Panel Roof Cold Roll Forming Machine / Building Material Making Machinery, the finished product are of many features,such as simple shape,large wave height,high intensity and good adhesiveness when pouring the concrete together with the welded steel wire net on-site,in the high story building,it not only can save steel mould board,but also reduce the bearing of the floor: on basis of equal capacity,it reduces the steel amount of engineering useage,so that it saves cost of investment. The 2W/3W-Deck Steel Decking Floordeck W Profile Ribdeck Structural Construction Steel Panel Roof Cold Roll Forming Machine / Building Material Making Machinery consists of uncoiler and its base,infeed guides,fixed position driven forming stations,shearing device,hydraulic station,PLC control console and so on. Our company has dozens of profile models for this series roll forming machine. We can design different kinds of profile and fitting for steel deck machine,as per customers' requirements.

Product Parameters2W/3W-Deck Steel Decking Floordeck W Profile Ribdeck Structural Construction Steel Panel Roof Cold Roll Forming Machine / Building Material Making Machinery

1. The Workflow Of Floordeck Panel Roll Forming Machine: Decoiler--Roll Forming--PLC System--Hydraulic System--Cutting--Output Table2. Product Descriptions Of Floordeck Panel Roll Forming Machine:

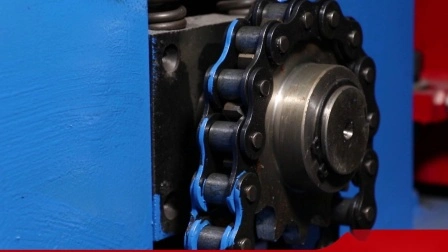

| 1) Main forming machine size: 12m*1.6m*1.6m2) Shaft Stations: 24 Stations 3) Materials: Color Steel Coil, Galvanized Steel Coil4) Materials width: 914mm-1250mm or customize.5) Materials Thickness: 0.3-0.7mm6) Shater Diameter: 75mm or 80mm or 90mm7) Drive Way: By chain8) Chain Size: 2.0 inch9) Machine Frame: 400H Steel10) Machine Power : 11KW+11KW11) Voltage: 380V/50HZ/3PH ( Can Customize according to your requirement)12) Warranty: one year for free. We provide easy broken parts for free. |

3. Finish Product Of Floordeck Panel Roll Forming Machine

4, Hydraulic Cutter Of Floordeck Panel Roll Forming Machine:5, Main Floordeck Panel Roll Forming Machine:

6. Component Of Floordeck Panel Roll Forming Machine7. Our Advantage8. Packaging & Shipping

9. Related Customize Products

Certifications

1. Q: Do you have after-sales support? A: Yes, our company provide technical support. If You need our technical engineer to go to your factory, we can send our engineer to you fatory.2

Q: How to visit your company? A: Fly to Beijing airport or Tianjin airport, we can pick you up. 3. Q: How to get a quote? A: Be sure to give me the profile and tell us the materials thickness. If not, I'll give you some advice. Let us know if you have other requirements, such as your desired speed, power and voltage.4. Q: Are you a trading company or a factory? A: We are factory. Welcome to visit our workshop.5. Q: Can you take care of shipping? A: Yes, please tell me the port of destination or address. We have rich experience in transportation.6. Q: How long can the machine be manufactured? A: Normally, an ordinary roll forming machine can complete it within 45 working days. If you need a machine urgently, we can do it for you in less than a month