Standing Seam Panel Forming Machine Self Lock Roofing Panel Machine Roll Forming Machine

standing seam panel forming machine self lock roofing panel machine TO AVOID OIL CANNING,WE CAN MAKE STIFFENING RIB AS Y

Basic Info.

| Model NO. | zh |

| Certification | CE |

| Condition | New |

| Customized | Customized |

| Usage | Roof, Wall |

| Transmission Method | Electric |

| Transport Package | Full Assembled |

| Specification | 4.5X0.85X1.4 |

| Trademark | ZH |

| Origin | Hebei, China |

| HS Code | 8455221000 |

| Production Capacity | 20 Sets Per Month |

Product Description

standing seam panel forming machine self lock roofing panel machine

TO AVOID OIL CANNING,WE CAN MAKE STIFFENING RIB AS YOUR REQUEST.

standing seam panel forming machine self lock roofing panel machine standing seam panel forming machine self lock roofing panel machine Specifications

| Technical Datas standing seam panel forming machine self lock roofing panel machine | ||

1 | Material Width | 290-600mm |

2 | Effective Width | 220-530mm |

3 | Thickness of Coil | 0.5-0.8mm |

4 | Application | standing seam roof panel |

5 | Estimated Dimension | 1500mmX1100mmX1200mm |

6 | Total Weight | 1.9 Tons |

7 | Main Power | 1.5KW |

8 | Decoiler | Manual or Hydraulic Decoiler |

9 | Inner Diameter | 508mm |

10 | Outer Diameter | 600 |

11 | Loading Weight | 4-5T |

12 | Forming Speed | 0-11m/min |

13 | Forming Station | 6 stations |

14 | Bracket | Welded with 36 # I-steel |

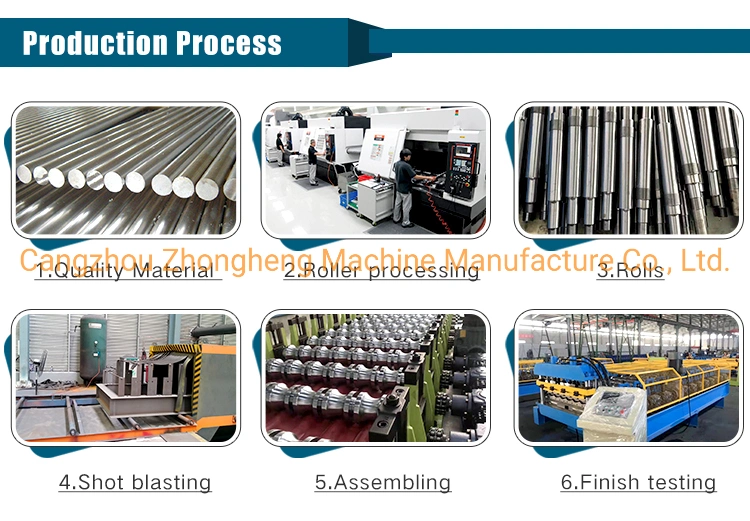

15 | Material of Shaft | High Grade forged 45# Steel with 1st Rough Finished and then 2th Refined Finished |

| 16 | Diameter of the Roll | 60mm |

17 | Material of Roller | High Quality Cr12 Quenched HRC58-62 ° |

18 | Processing Technology | Rough Processing ---Refined Processing--Hard Chromium Plating. |

19 | Material of Rack | Complete Welded Structure of A3 Steel Plate 20 mm Thickness |

20 | Transmission | Chain driving |

21 | Material of cutting blade | Cr12 with Quenched Treatment 60-62 ° |

22 | Cutting system | Hydraulic Stop or Tracking Cutting |

23 | Voltage | 380V/50HZ/3 Phase or as Customer Require |

Packing and Shipping

1. Metal roofing sheet roll forming machine iron roofing sheet making machine need one 20/40 feet container to load .2.We have professional technicians for loading to make sure machine has no damage.3.Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.

Company Introduction

FAQ

1. Can you make the machine according to my design or photo type?

A: Yes. We have an experienced engineers to work out the most suitable design and production plan for the machine.

2: How can we be assured that you will deliver us quality machine with spare parts?

A:1. Customers to send the technical people to our factory for checking the quality.

2.We can send the technicians to the buyer`s factory for the installation and trainning .

3.What about your warranty?

A: Within the One-YEARS period, we could supply you the replacement parts for free .

If any damaged parts caused by quality problems after two years,we will also help but customer pay the cost .

More information please send inquiry to us , you will get reply within 12 hours !

previous:

2W/3W

Send to us